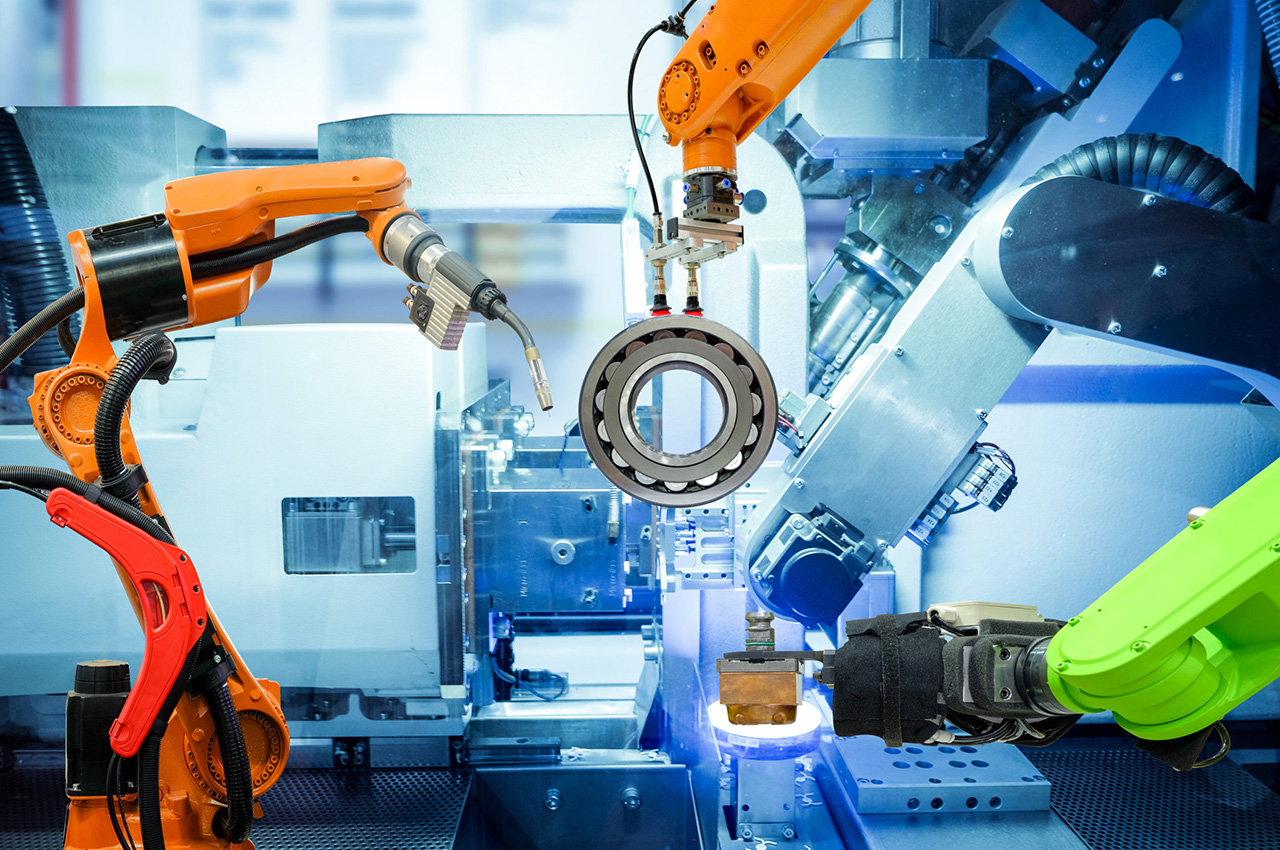

Automotive

Accurately predicts a car's behavior in a collision and the effects of the collision upon the car's occupants.

With LS-DYNA, automotive companies and their suppliers can test car designs without having to tool or experimentally test a prototype, thus saving time and expense.

Aerospace

LS-DYNA is widely used by the aerospace industry to simulate bird strike, jet engine blade containment, and structural failure.

Aerospace applications include blade containment, bird strike (windshield, and engine blade) and failure analysis. With GENESIS, you can perform multidiscipline aerodynamic and structural design of a wing or reliability based design of a landing gear. 3DCS Software has been applied to reduce shimming, improve final assembly and reduce costs associated with non-conformance.

Sporting Equipment

Computers play a big part in our work, modern techniques allow us to look at how structures bend and vibrate and also how air and water flow around athletes and equipment.

These new tools make it possible to simulate how products perform in the real world and assess how changes in design may affect the sport. The changes we make may be to improve performance or to ensure regulations are upheld.

Research & Development

Research and innovation are key processes in our company to bring to our customers the latest technology

helping them to optimize their resources and competitivity.

Defense

DFETECH engineered solutions for the defense sector are manufactured to meet stringent performance standards

and can be implemented as a turn-key solution for existing equipment, processes, or systems.