Formability Simulation (FS)

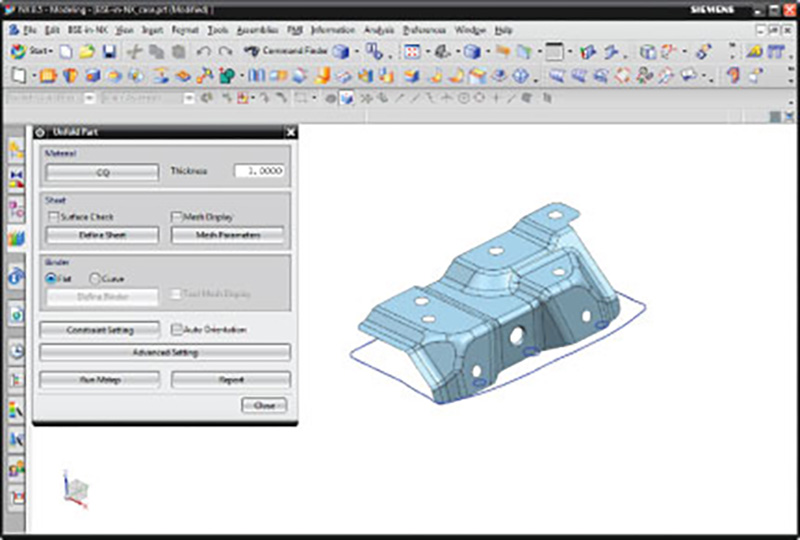

This module facilitates the rapid development & validation of single-station & progressive die designs.

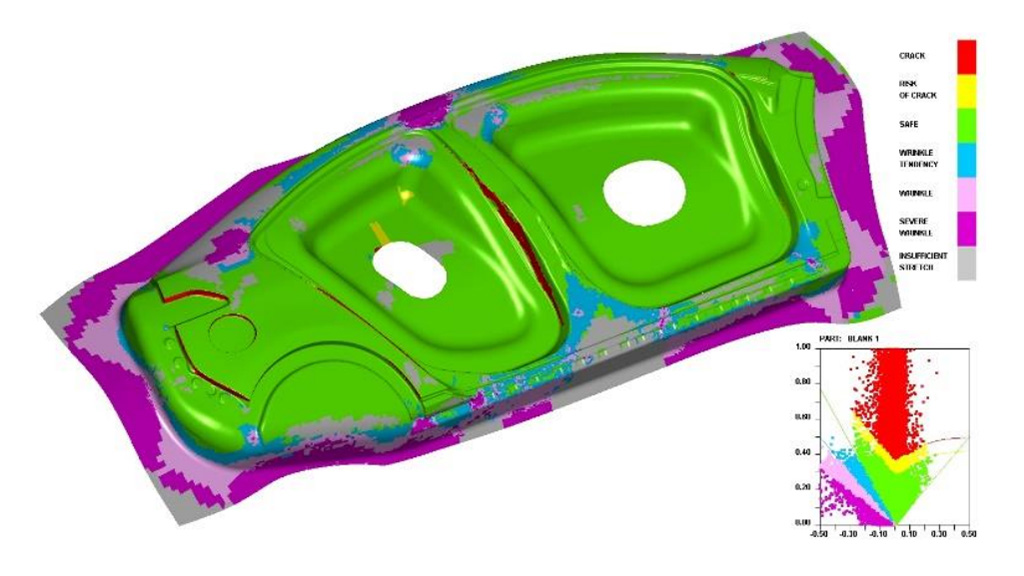

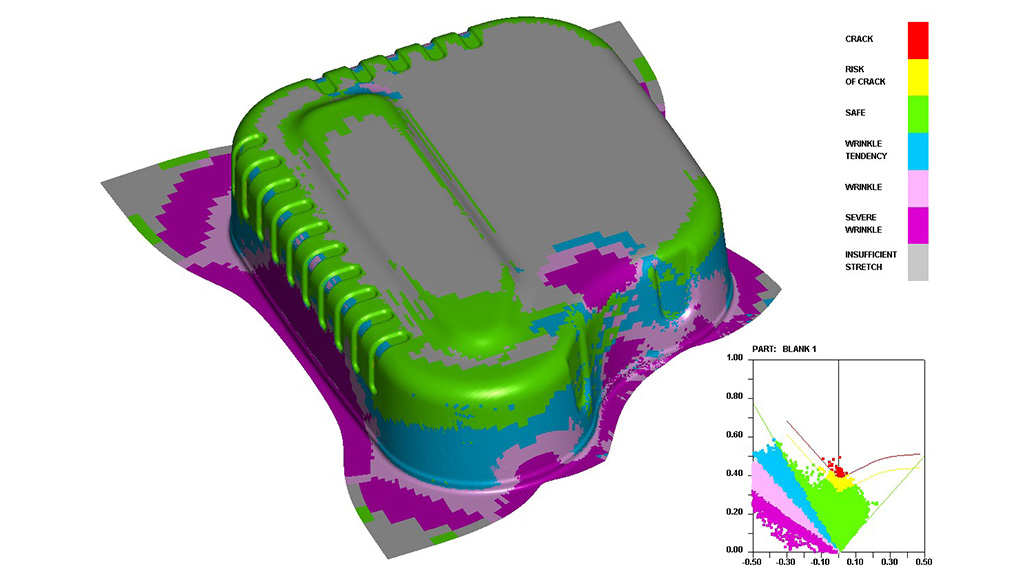

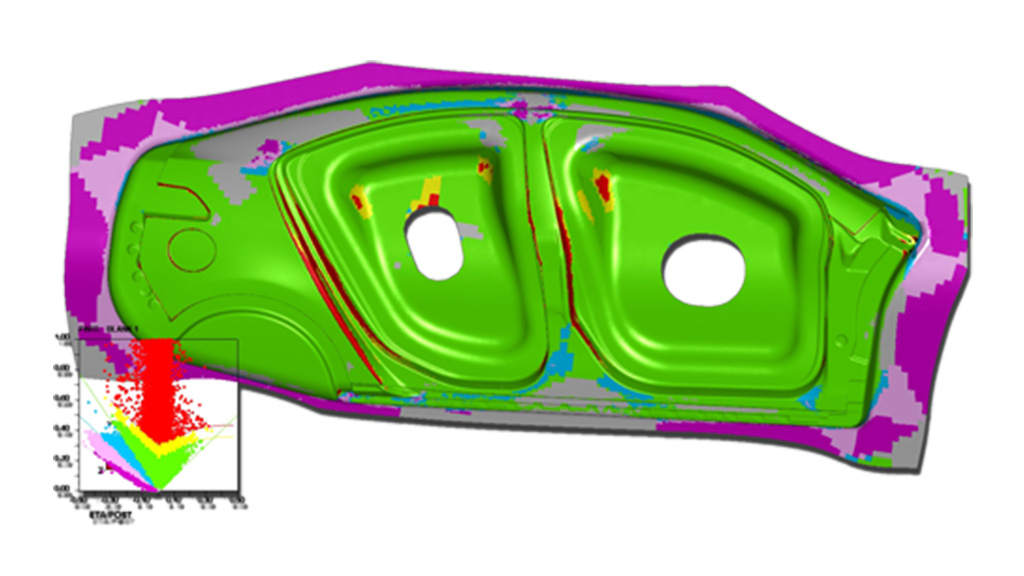

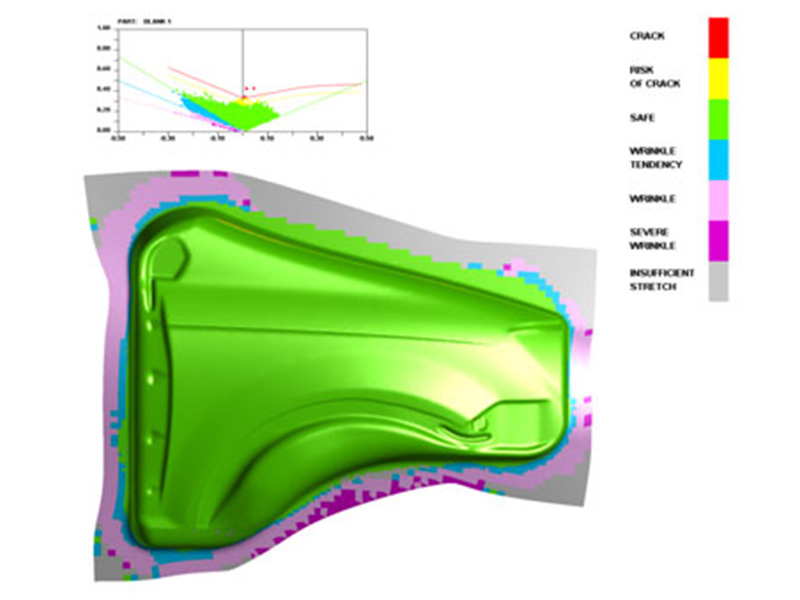

FS help to uncovers hidden problem areas & enables designers to optimize designs based on accurate forming results.

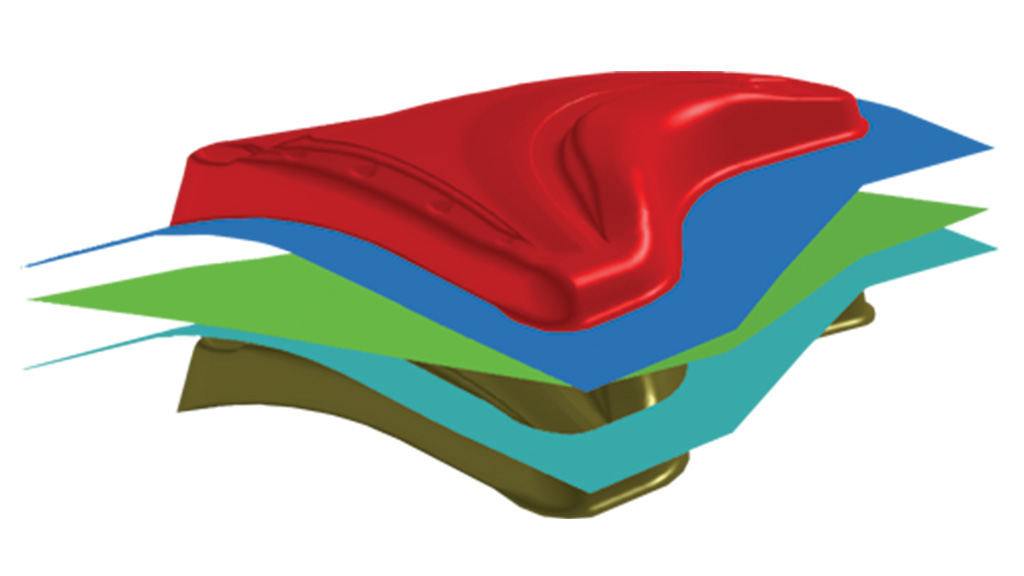

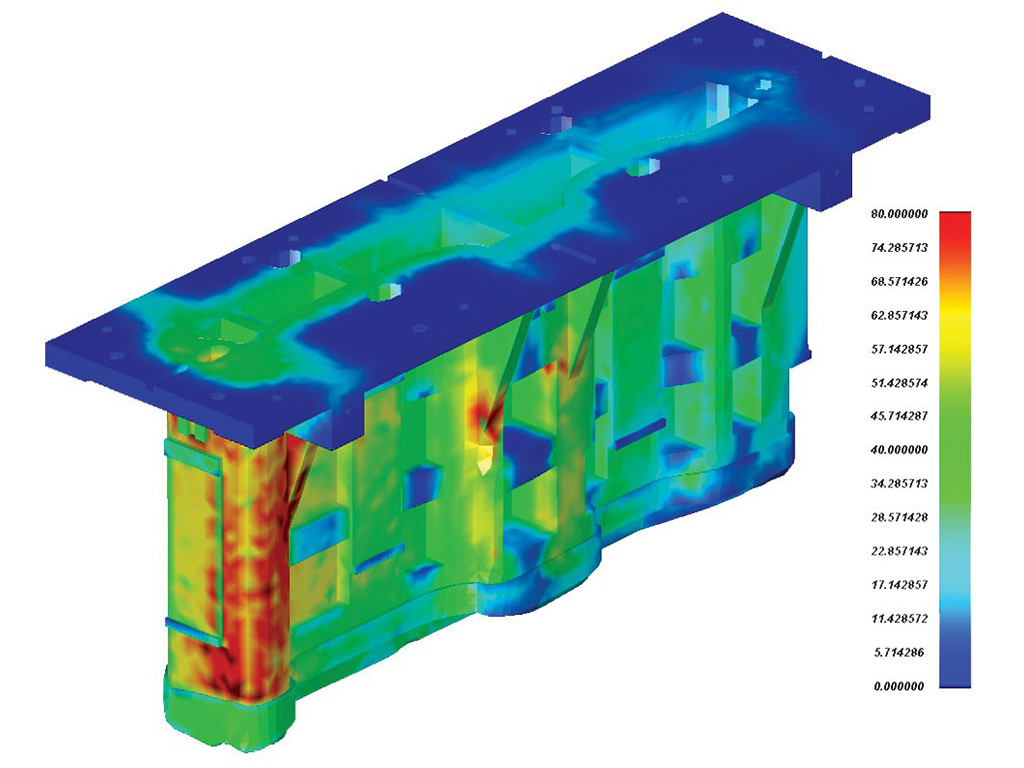

The Formability Simulation module uses LS-DYNA for accurate physics modeling, efficient calculation and in-depth simulation of the formability based on the die design. The FLD (forming limit diagram), thinning map, wrinkling, material draw-in, circular grid, light strip and skid mark results identify weaknesses of the die design.

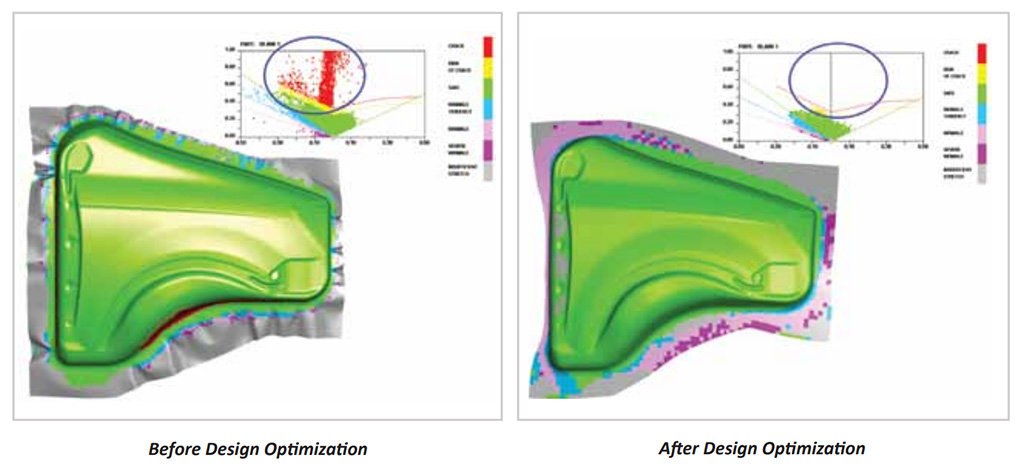

New! Optimization Capability

With DYNAFORM Version 5.9, the engineer can more effectively design drawbeads that restrict the blank from wrinkling & splitting during the forming process, significantly reducing the time required to achieve a formable part.

It streamlines the challenging and time consuming process of laying out drawbeads for large and complicated parts and guides the engineer to efficiently achieve optimum configurations for drawbead forces.

This feature streamlines die design, improves product performance and reduces manufacturing time by using simulation iterations as a search engine for the best possible design solution. As a result, higher performing, higher quality products can be developed, while greater manufacturing efficiency is achieved.