VPG

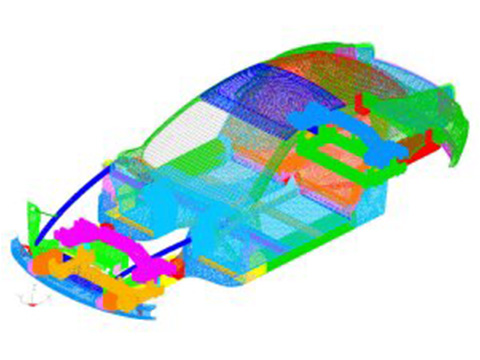

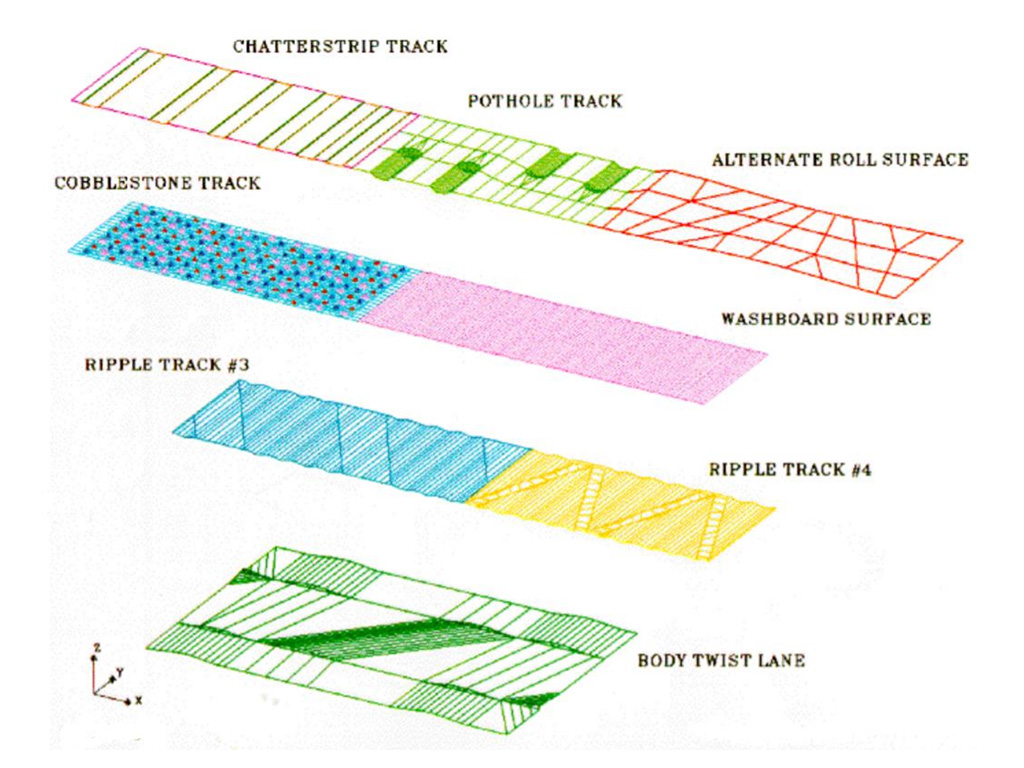

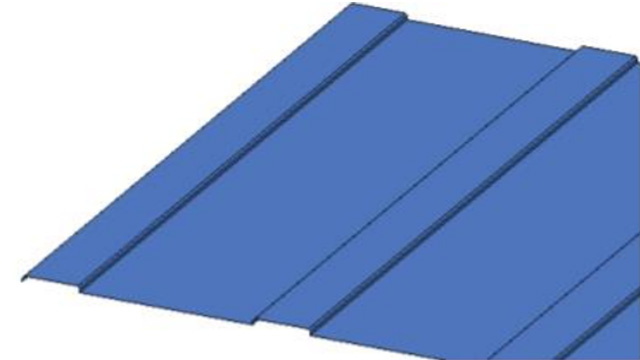

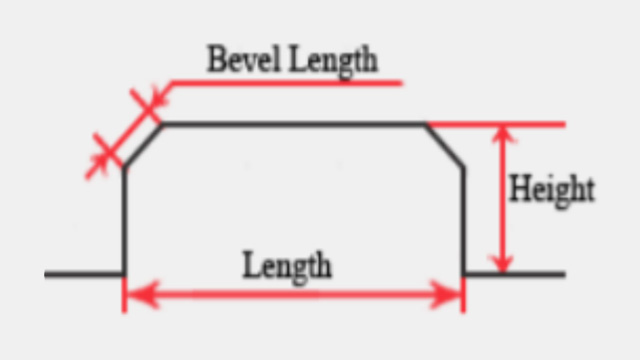

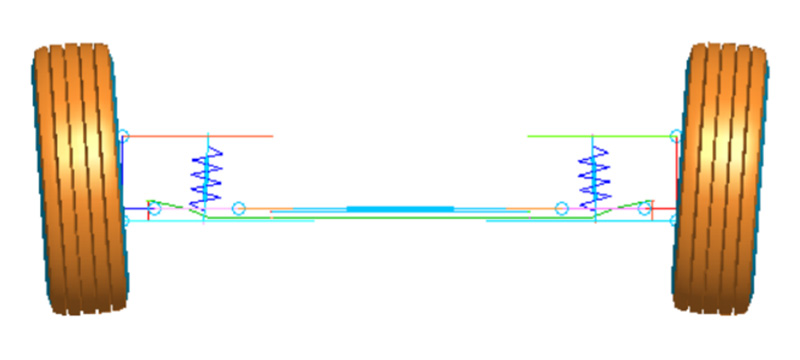

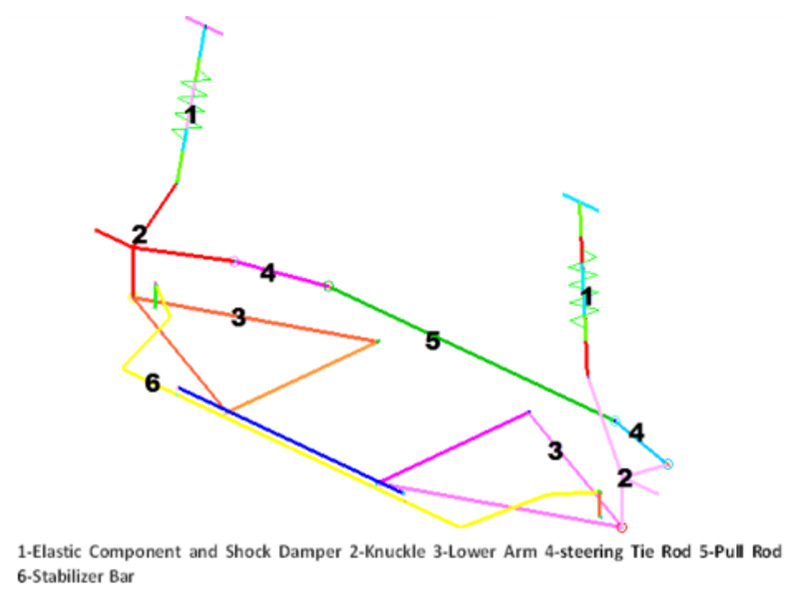

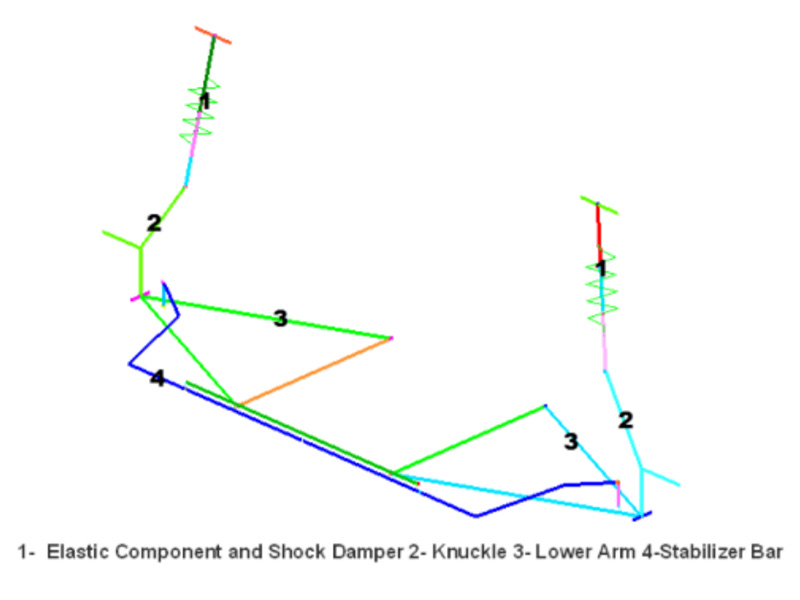

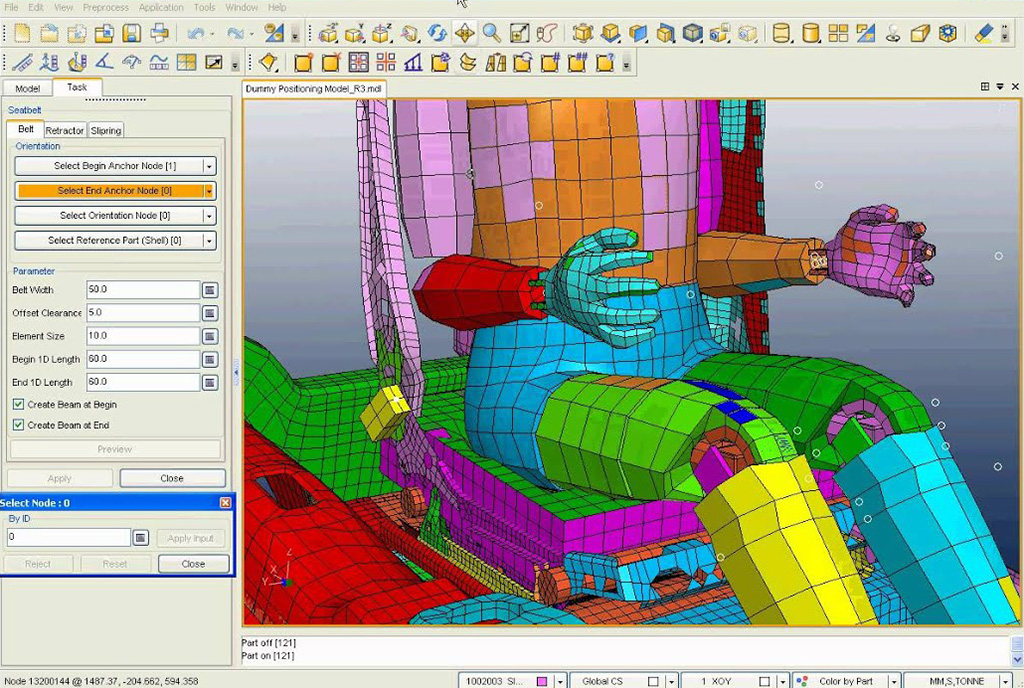

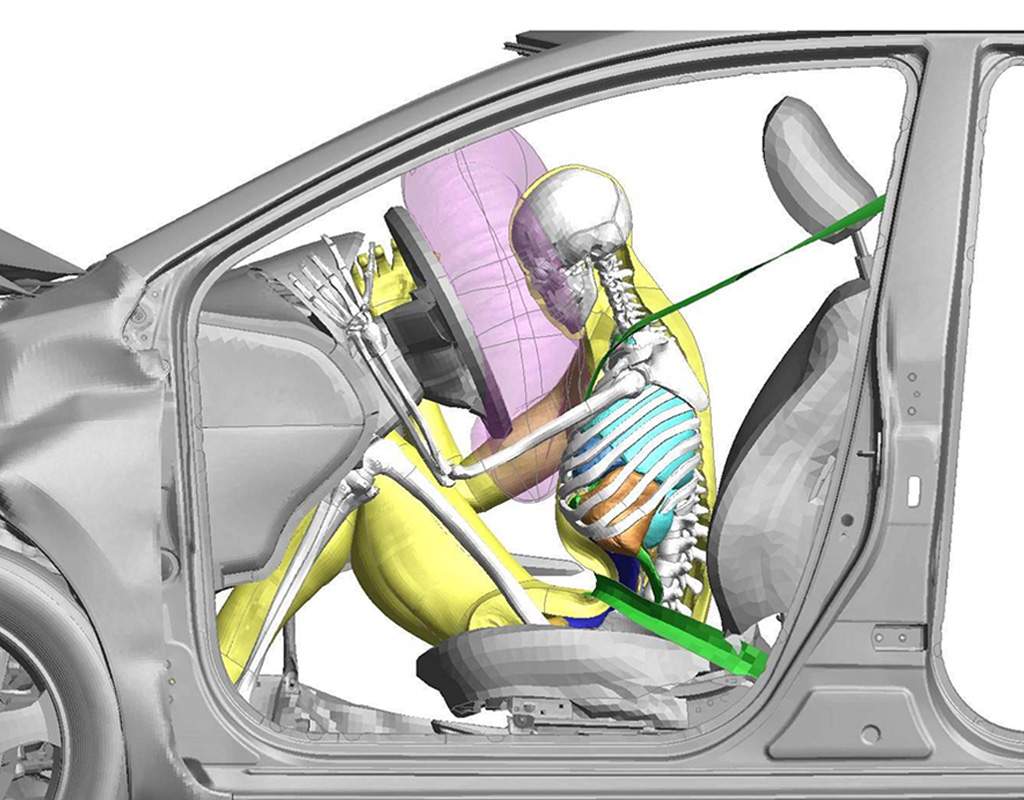

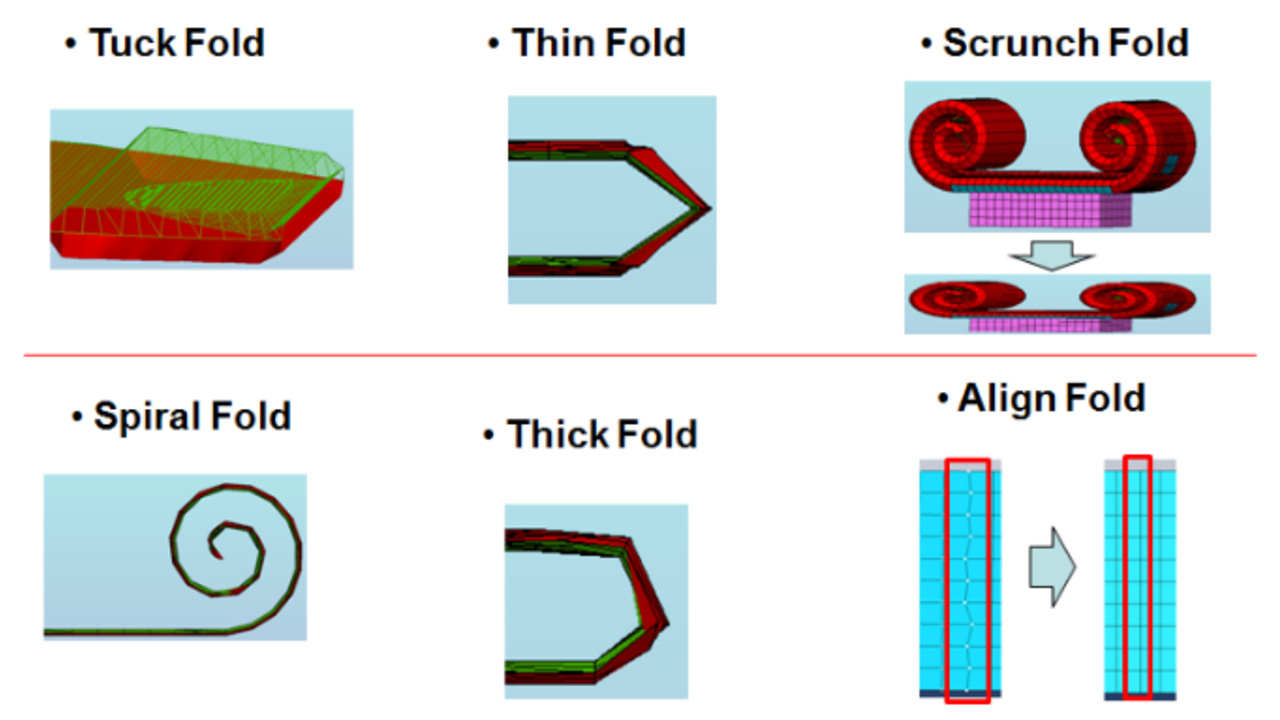

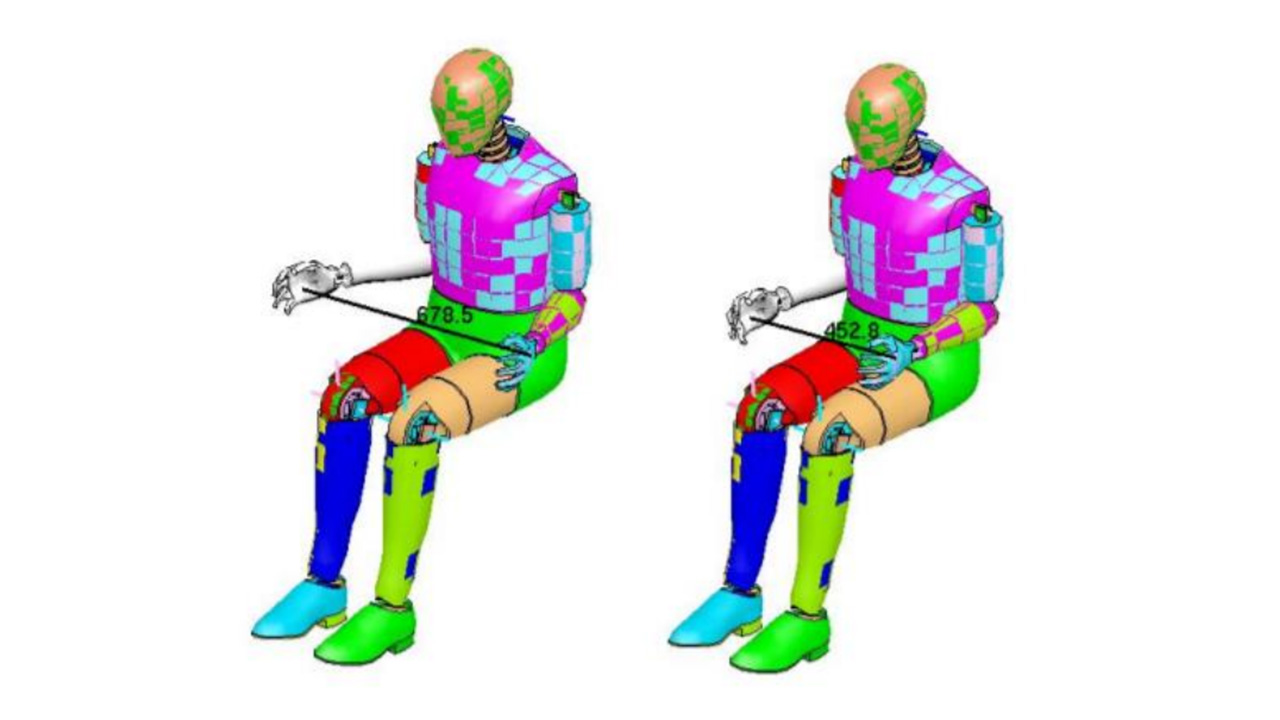

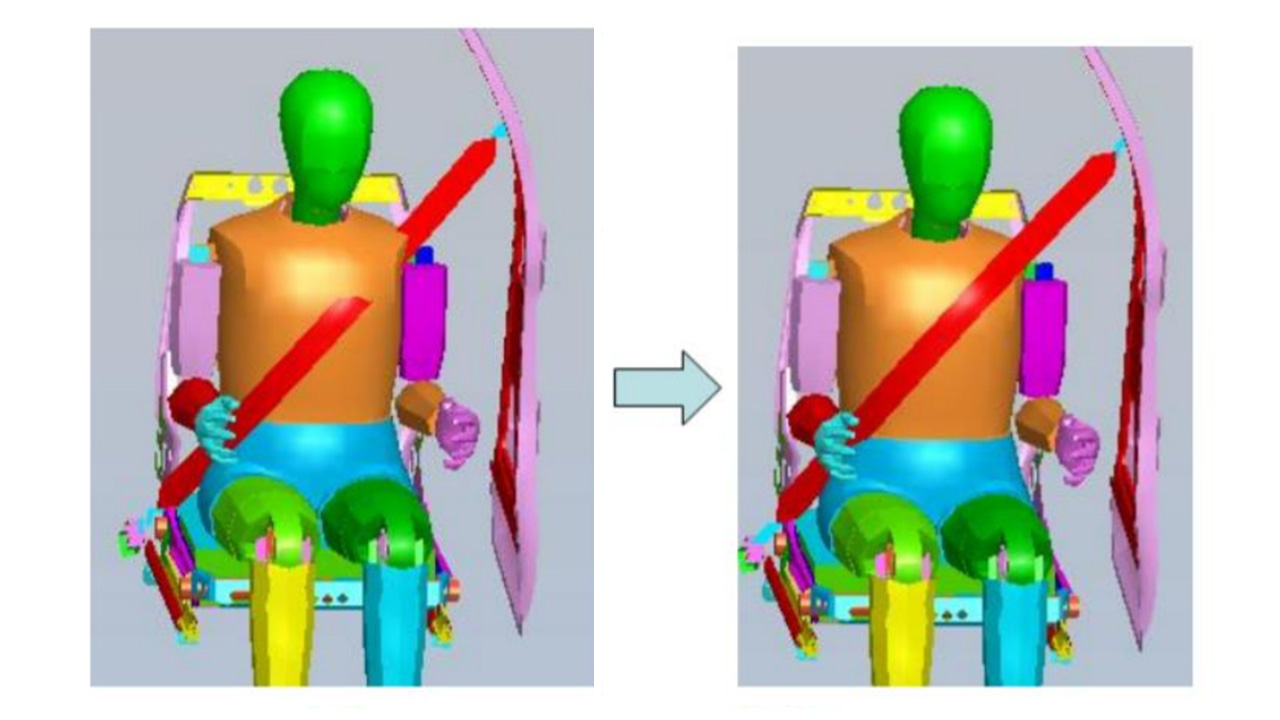

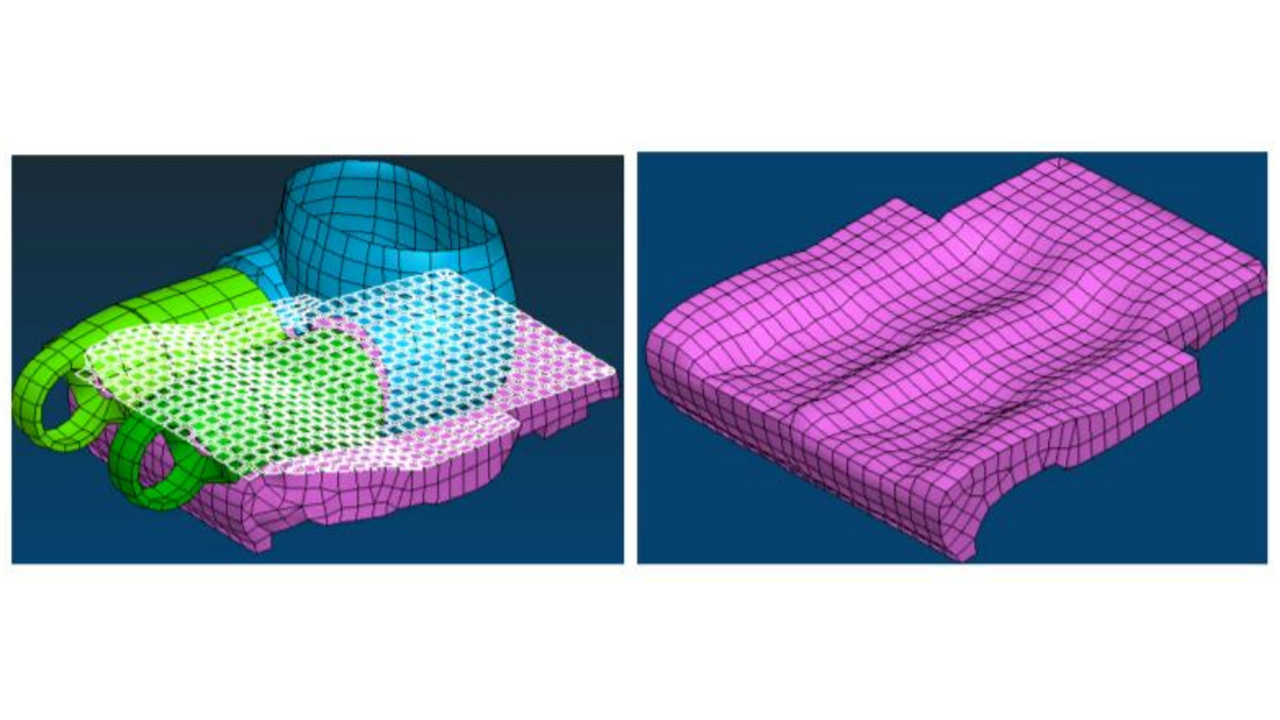

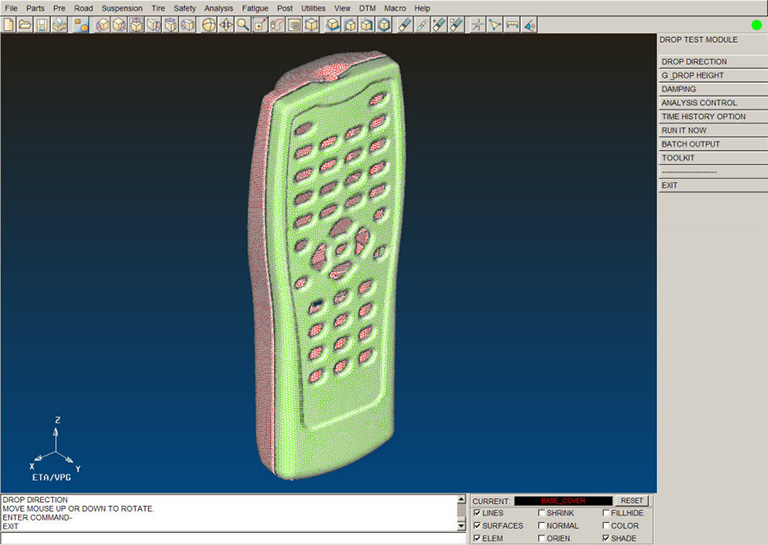

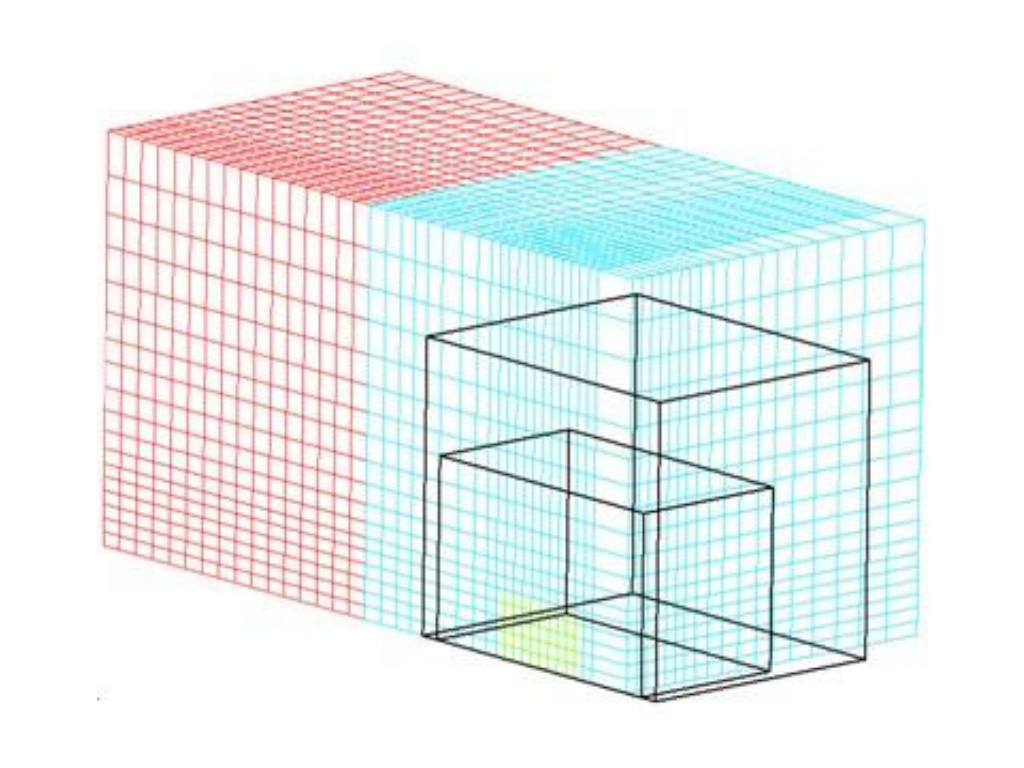

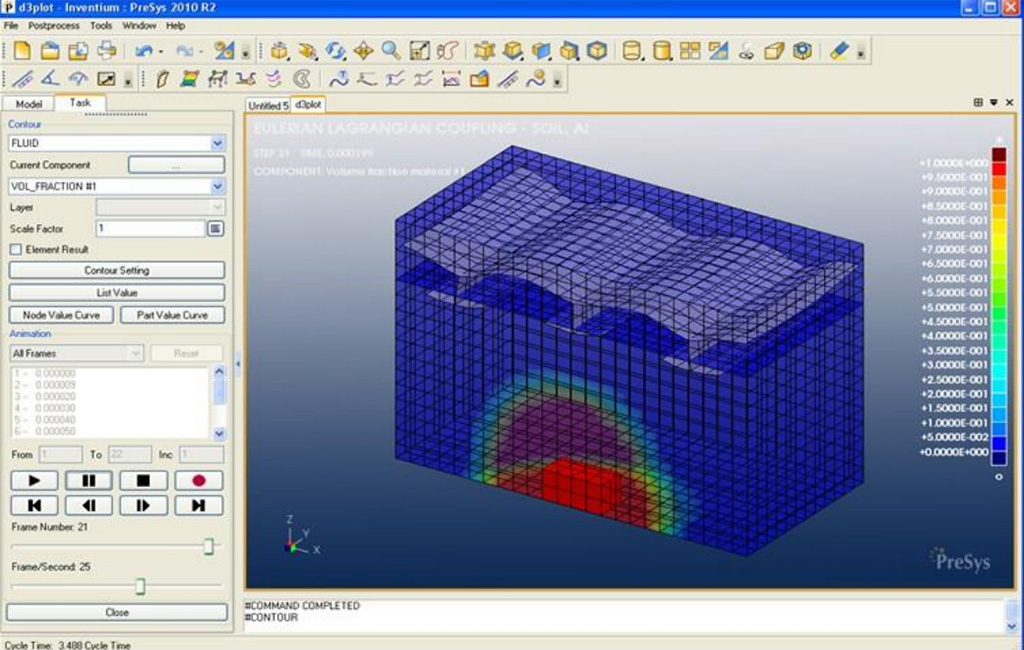

Virtual Proving Ground (VPG) module is a customized finite element tool developed for automotive industry. It is mainly used in the simulation of vehicle system level analysis, including the analysis of vehicle system fatigue life, nonlinear dynamic analysis of vehicle system, NVH analysis, collision safety and occupant protection

It is ETA's commonly used pre-processing and post-processing platform, which mainly use for security and structure.