QDM

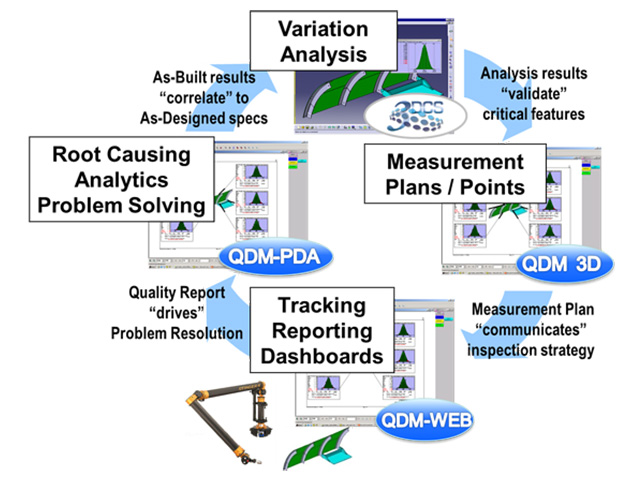

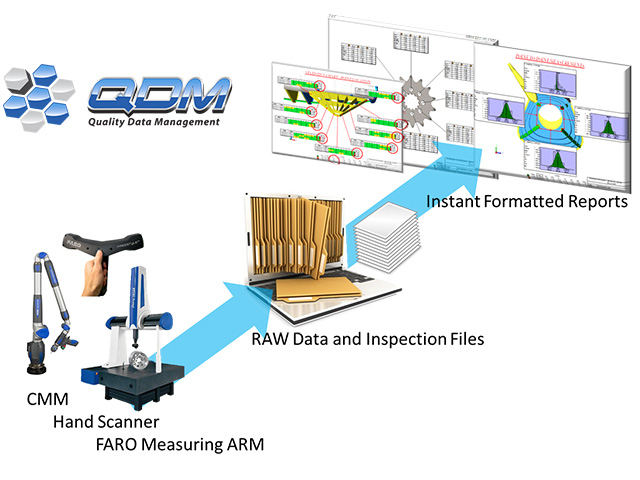

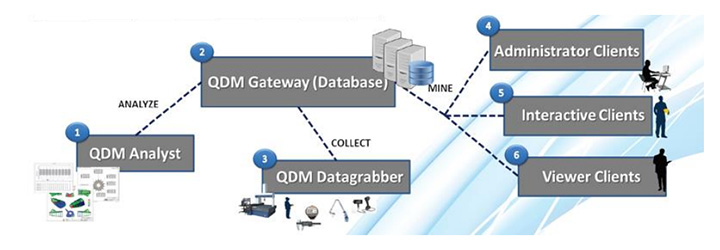

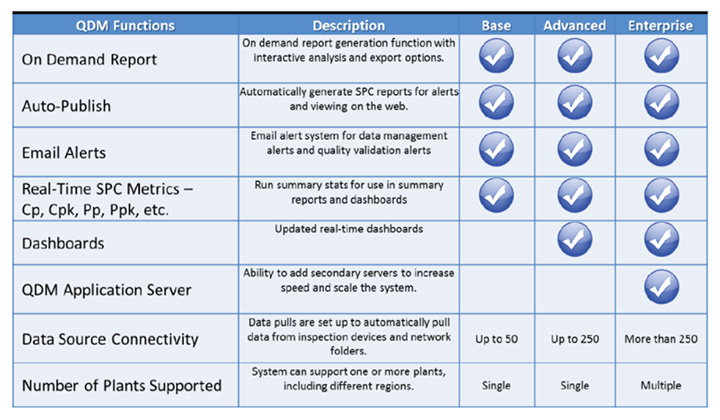

Quality Data Management (QDM) makes it easy to access within each organization or supplier by centrally managing quality data collected from multiple sites, and also generates reports automatically, and automatically alerts when status deviates.

An integrated management system for quality data that improves management efficiency. By utilizing the QDM system, quality data that tends to be buried can be useful information that the entire organization can access from business management to field technicians.

Features

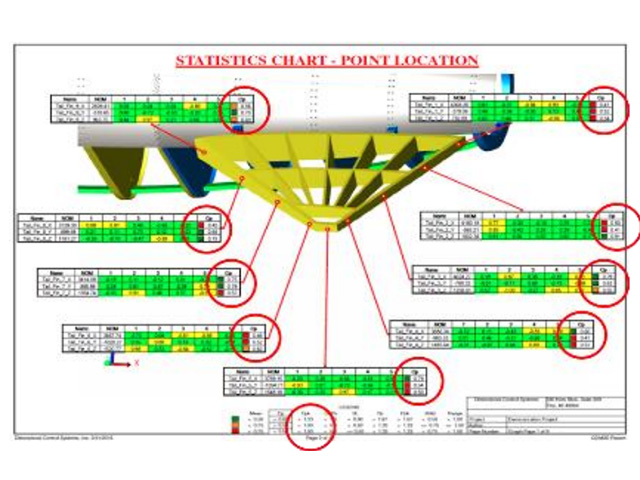

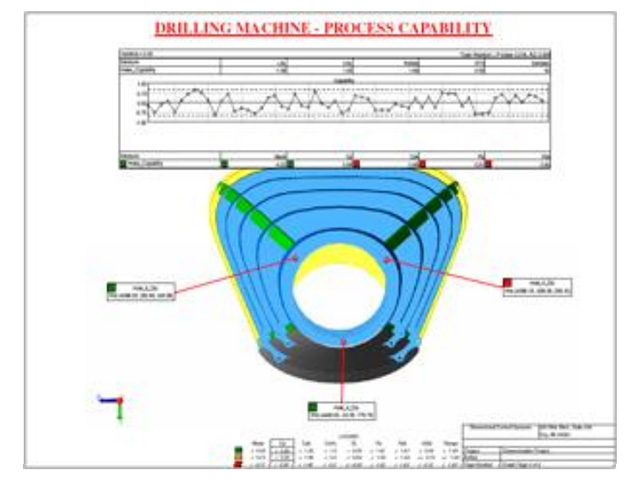

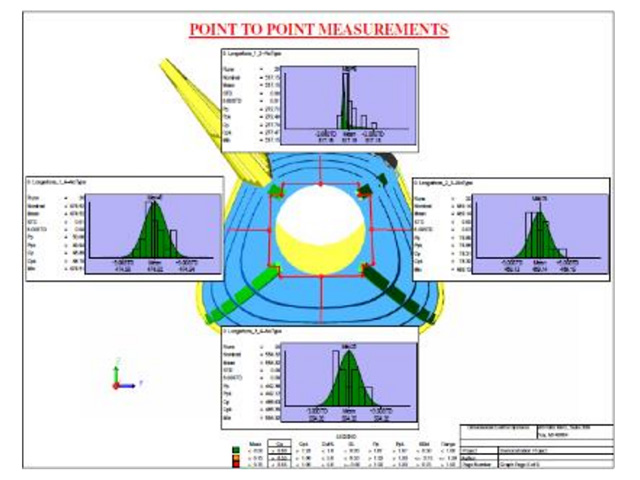

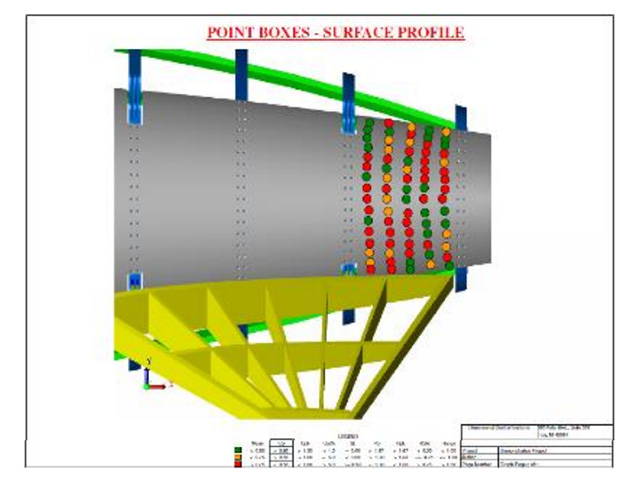

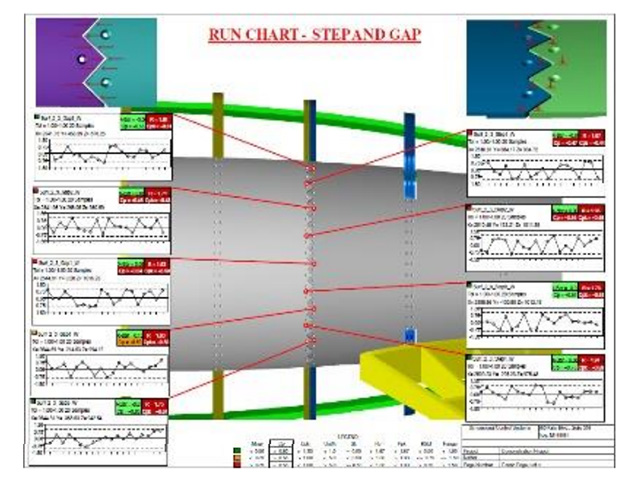

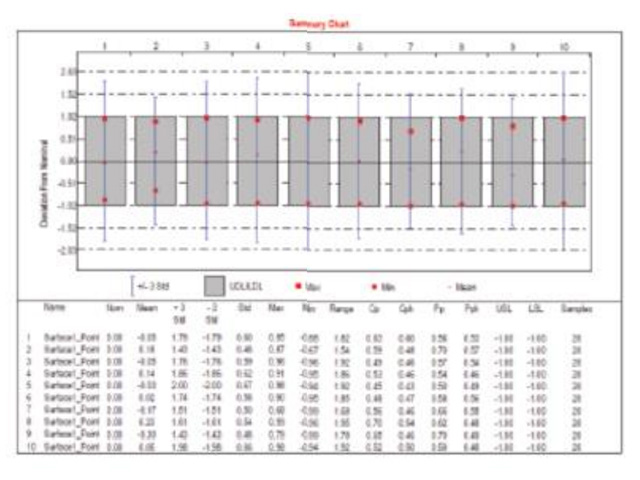

- Ability to customize dashboard (format) of quality data

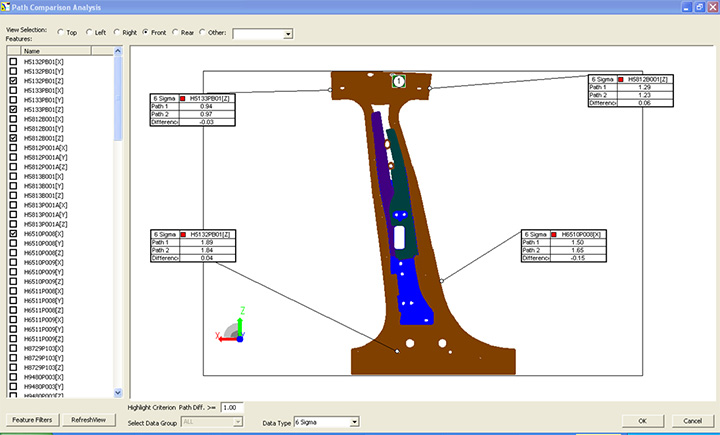

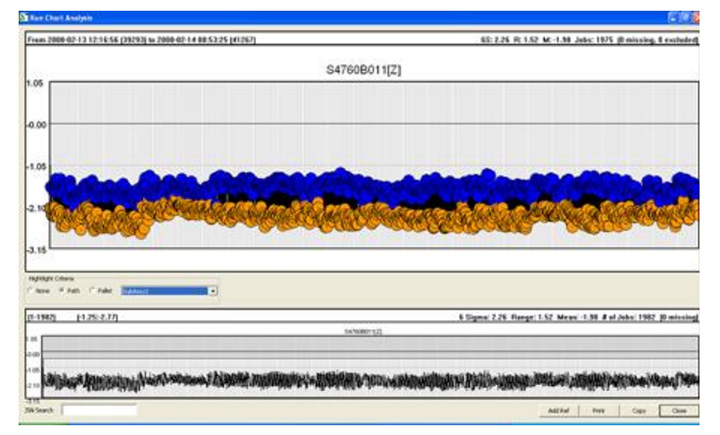

- Ability to automate quality data processing

- Central accumulation of quality data-improving traceability

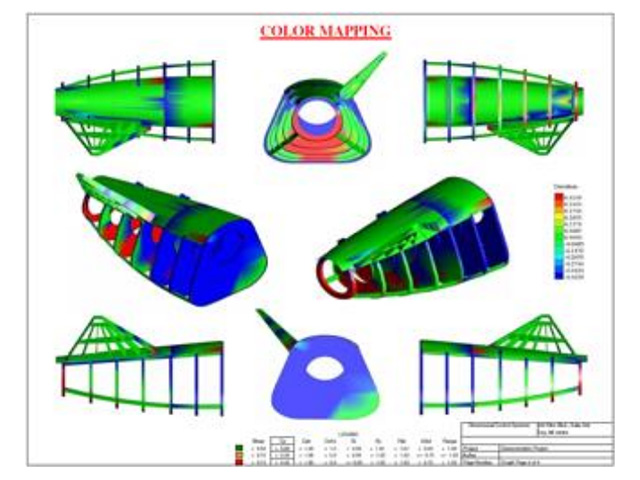

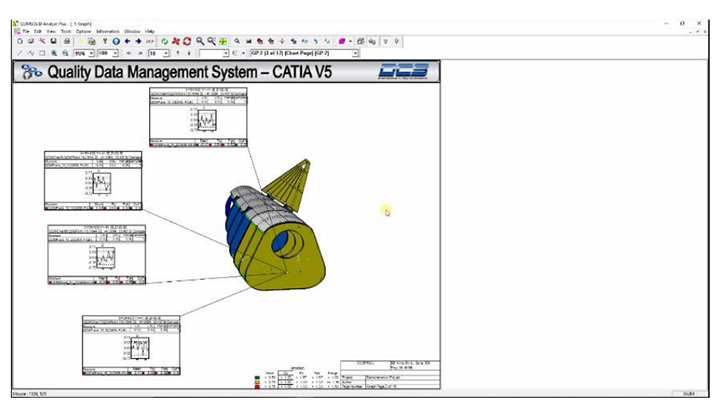

- Supports data from almost all measuring instruments in 3D measuring instruments, attribute gauges, handheld terminals and nondestructive testing etc

- Enables data management according to standards such as ISO 9000 series

- Web-based access to data from PCs, smartphones, tablets, etc.

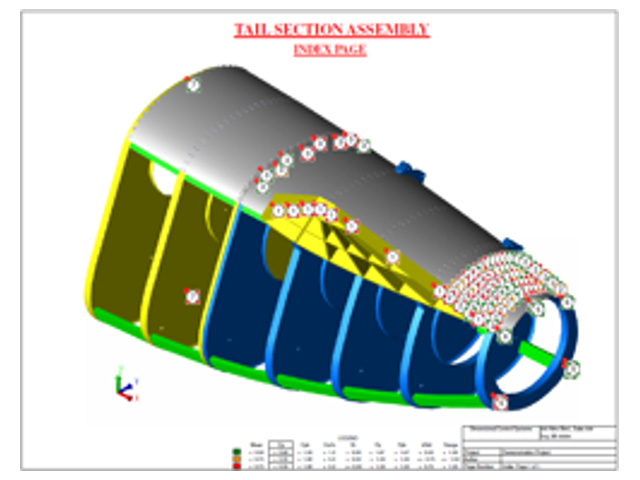

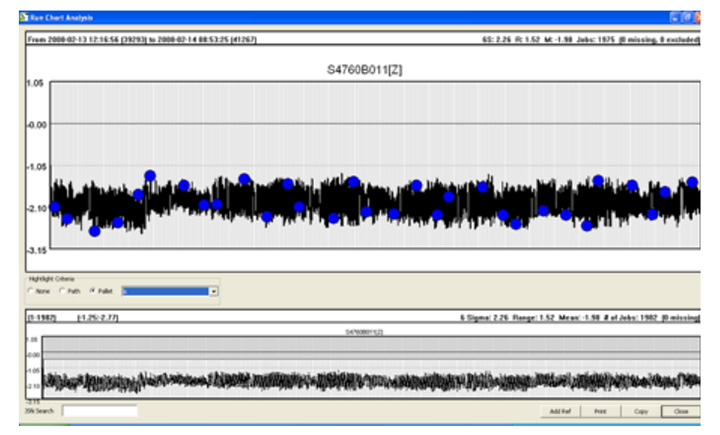

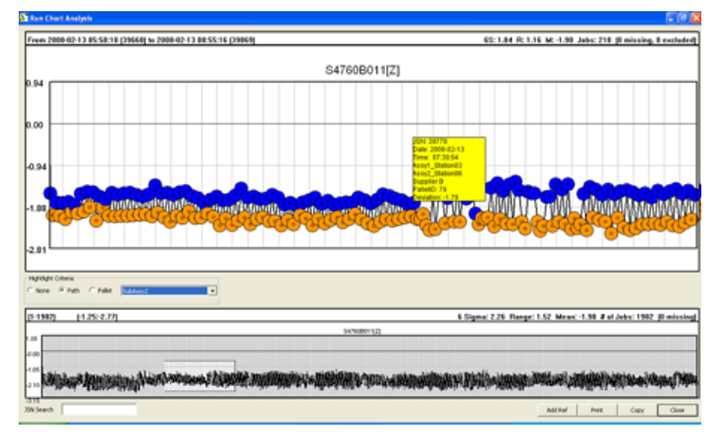

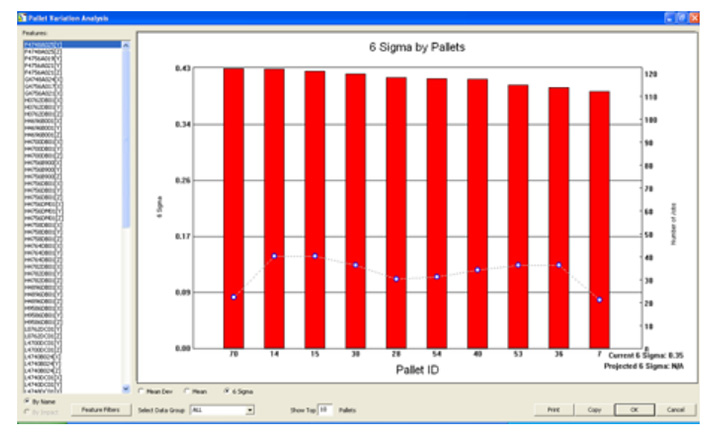

- Easy-to-read reports including graphics and measurement data

- You can easily create and customize templates

- High versatility for various measurement devices (Datagrabber cooperation)

- Web-based high accessibility

- Refinement and extraction of highly efficient data

- Standard document output